Picking a Pallet

At GPS Wood Pallets, Inc. we understand that sometimes knowing what type of pallet will suit your particular needs can be a bit confusing. The pallet information below can head you in the right direction, simply click on the icon to the right of a heading to learn more. As always, be certain to call us at 909-391-6127 or email us at info@gpswoodpallets.com with any questions!

Basic Information

Pallets 101

Types of pallets

Although pallets come in all manner of sizes and configurations, all pallets fall into two very broad categories: “stringer” pallets and “block” pallets. Various software packages exist to assist the pallet maker in designing an appropriate pallet for a specific load, and to evaluate wood options to reduce costs.

Stringer pallet

Stringer pallets use a frame of three or more parallel pieces of timber (called stringers). The top deckboards are then affixed to the stringers to create the pallet structure. Stringer pallets can have a notch cut into them allowing “four-way” entry.

Block pallet

Block pallets (also referred to as Manoj pallets) are typically stronger than stringer pallets. Block pallets utilize both parallel and perpendicular stringers to better facilitate efficient handling. A block pallet is also known as a “four-way” pallet, since a pallet-jack may be used from any side to move it.

Two-way or Four-way Entry

Entry refers to the number of sides of a pallet that can be entered by a forklift or pallet jack. While two-way entry pallets may be a little less expensive, the four-way entry offers more flexibility, especially in loading trailers where turning the pallet 90 degrees allows far better utilization of space, thereby lowering shipping costs.

Because a forklift utilizes relatively thin forks and stringers are generally notched or raised, it is able to enter either type of pallet from all four sides; however, oftentimes, a pallet jack, because its lifting wheels are built into the thicker forks, can only enter a four-way pallet from two sides, not all four.

Two-way pallets: Designed to be lifted by the deckboards. In a warehouse, the deckboard side faces the corridor. For optimal cubage in a warehouse, the deckboard dimension should be the shorter. This also helps the deckboards be more rigid.

Four-way pallets: Generally used for heavier loads. Forks go under stringers instead of deckboards. (Compare to piers (forks) that support floor joists (stringers), which in turn support the floor structure (deckboards) in a house.

Common Sizes of Recycled Pallets and their Typical Industries

48 x 40 – #1 Grade: Grocery, Agriculture, Food Processing

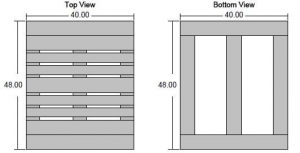

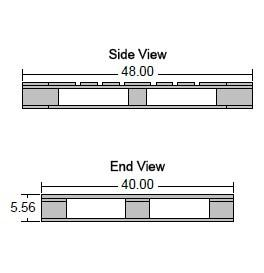

Most 48″ x 40″ pallets are manufactured as Grocery Manufacturer’s Association, or GMA, style pallets. Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 5 1/2″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 5 1/2″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.

Most 48″ x 40″ pallets are manufactured as Grocery Manufacturer’s Association, or GMA, style pallets. Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 5 1/2″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 5 1/2″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.48 x 40 – #1 Grade with 6 inch lead boards: Grocery, Agriculture, Food Processing

Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 6″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 6″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.

Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 6″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 6″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.48 x 40 – #1A Premium Grade GMA: Food-grade requirements

This pallet has GMA board configuration. It has no visible signs of repair. Bright wood color. Minimal damage to wood. Often indistinguishable from a new pallet. It is ideally suited for delivery to food and grocery customers. Sometimes referred to as a Sam’s Grade Pallet or a “food-grade” pallet. Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 5 1/2″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 5 1/2″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.

This pallet has GMA board configuration. It has no visible signs of repair. Bright wood color. Minimal damage to wood. Often indistinguishable from a new pallet. It is ideally suited for delivery to food and grocery customers. Sometimes referred to as a Sam’s Grade Pallet or a “food-grade” pallet. Stringers are 1 3/8″ x 3 1/2″ x 48″. Stringers have two notches in the side to allow for forklift entry. This makes it a 4-way pallet. Top and bottom deck boards are 5/8″ thick. Top of pallet has a 5 1/2″ x 40″ board on each end, and five 3 1/2″ x 40″ boards in the center. Bottom of pallet has a 5 1/2″ x 40″ board on each end, and three 3 1/2″ x 40″ boards positioned between the notches.48 x 40 – Heat-Treated Export Pallet: Exporting to IPPC & ISPM-15 compliant nations

If you ship your products outside the US, the pallets you use will be required to comply with the International Phytosanitary Measure known as ISPM 15. Compliance involves “Heat Treating” pallets to reduce the risk of introduction and/or spread of quarantined pests.

If you ship your products outside the US, the pallets you use will be required to comply with the International Phytosanitary Measure known as ISPM 15. Compliance involves “Heat Treating” pallets to reduce the risk of introduction and/or spread of quarantined pests.48 x 40 – #2 Grade: Grocery, Agriculture, Industrial

Typically this is a GMA which has had stringer damage that has been repaired by attaching an additional stringer alongside the damaged one. This is commonly referred to as a companion stringer, sister stringer, or double stringer.

Typically this is a GMA which has had stringer damage that has been repaired by attaching an additional stringer alongside the damaged one. This is commonly referred to as a companion stringer, sister stringer, or double stringer. 48 x 40 – Block pallet, Costco spec: Shipping to Costco chain stores

5.5.2 DESIGN pallets with PDS™ SOFTWARE, and manufacture accordingly. Pallets must be machine built

PDS™ (PALLET DESIGN SYSTEM™) is required to ensure design conformance with necessary safety and performance criteria.

5.5.4 PDS™ GENERAL SPECIFICATIONS

‐A Classification:

– 48”x40”

– Block class, perimeter base (full 4‐way entry).

– Double‐face, non‐reversible

– Multiple‐use/reusable

‐B Lumber:

– New lumber (no processed/engineered wood or composites)

– Standard grade or better

– Softwood must be kiln‐dried

5.5.7 PDS™ DURABILITY/SERVICE LIFE SPECIFICATIONS

‐A Service Environment Conditions: Average Handling and Treatment; Heavy‐Duty Loads; Dry Environment

‐B Predicted Cycles Until First Repair 6 or more; Predicted Service Life 24 or more cycles.

5.5.8 COMPONENT LUMBER DIMENSIONS

‐A TOP DECK deckboard/stringerboard style; flush

– 11/16” (.688”) thick x 40” long

– Lead‐edges consisting of (at least) 2 butted boards; outermost lead‐edge boards 5.5” wide

– At least one other board 5.5” wide; all other boards at least 3.5” wide

– Interboard gap/deckboard span no more than 1.75”; top‐deck coverage at least 78%

‐B BOTTOM DECK perimeter‐base; flush

– CHAMFERED (stop style; 0.34” deep)

– 5 boards

– 5.5” wide x 11/16” (.688”) thick; 2 boards 40” long, 3 boards 37” long

– JOINTS MUST BE BUTTED

‐C STRINGERS/STRINGERBOARDS

– 3 boards

– 5” to 5.5” wide; must be same width as blocks

– 11/16” (.688”) thick x 48” long

‐D BLOCKS

– 5” to 5.5” wide; must be same width as stringers/stringerboards

– 3.5” tall

– 6 outer blocks 7.5” long; 3 inner blocks 3.75” long

48 x 48 – Drum Pallet: Fruit Juices, Chemicals

Designed to hold up to four 55-gallon drums or other bulky items. Tough, durable wood. Double stringer provides added strength. 2-way forklift access.

Designed to hold up to four 55-gallon drums or other bulky items. Tough, durable wood. Double stringer provides added strength. 2-way forklift access.44 x 44: Chemicals

42 x 42: Telecommunications, Paint

40 x 48 (Reverse Pallet): Dept. of Defense, Brick & Block, Cement

Height 3″, Width 40″, Length 48″ (40 x 48). When stating the pallet size always give the stringer dimension first. Some call it the runner which is the direction the fork lift enters the pallet. For example the standard pallet is a GMA or a 48 x 40, it is not a 40 x 48. We use the leading dimension to determine the stringer length. This is a reverse, double sided pallet.

Height 3″, Width 40″, Length 48″ (40 x 48). When stating the pallet size always give the stringer dimension first. Some call it the runner which is the direction the fork lift enters the pallet. For example the standard pallet is a GMA or a 48 x 40, it is not a 40 x 48. We use the leading dimension to determine the stringer length. This is a reverse, double sided pallet.48 x 42 Pallets: Beverage, Chemicals

44 x 56 Can and Glass Pallets: Beverage

Common Sizes of New Pallets and their Typical Industries & Uses

48 x 40 – 5/8″ thick hardwood: Grocery, Food Processing, Industry

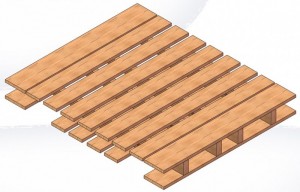

A new 48″ x 40″ 4-way 5/8″ wood pallet, also called a GMA pallet or standard pallet in many industries. Wood pallets are cost effective & are recyclable and made from renewable resources.

A new 48″ x 40″ 4-way 5/8″ wood pallet, also called a GMA pallet or standard pallet in many industries. Wood pallets are cost effective & are recyclable and made from renewable resources.Additional Sizing Information

Stringers: (3) 1-3/8″ x 3-1/2″ x 48″

Top Deck Lead Boards: (2) 5/8″ x 5-1/2″ x 40″

Top Deck Boards: (5) 5/8″ x 3-1/2″ x 40″

Bottom Deck Lead Boards: (2) 5/8″ x 5-1/2″ x 40″

Bottom Deck Boards: (2) 5/8″ x 3-1/2″ x 40″

48 x 40 – 1/2″ thick hardwood: Grocery, Food Processing, Industry

40 x 48 – Wing pallet, heat treated pine: Cylinders

Pallets can be single or double wing (double wing pictured)

Pallets can be single or double wing (double wing pictured)Glossary of Terms

Glossary

A

Annular Nail

Pallet nail with annular (circular ring) threads rolled onto the shank

B

Banding Notch – See Strap Slot

Bin

Four-sided superstructure to be mounted on a pallet base, with or without a cover; also known as a box or container bin pallet

Block

Rectangular, square or cylindrical deck spacer, often identified by its location within the pallet as corner block, end block, edge block, inner block, center or middle blocks

Block Pallet

A type of pallet with blocks between the pallet decks or beneath the top deck

Butted Deckboard

An inner deckboard placed tightly against an adjacent lead deckboard during pallet assembly

Bottom Deck

Assembly of deckboards comprising the lower, load bearing surface of the pallet

C

CAD

Computer-aided-design software that allows the design of the “right” pallet at the best value; see Pallet Design System© (PDS©)

Captive Pallet

A pallet intended for use within the confines of a single facility, system or ownership; not intended to be exchanged

Chamfered Deckboards

Deckboards with edges of one or two faces beveled, either along the full or specified length of board or between the stringers of blocks, allowing easier entry of pallet jack wheels

Closed Distribution System

Shipping system restricted to moving goods between specified plants and facilities

Collar

Collapsible wooden container or bin which transforms a pallet into a box

Cost-Pass-Through

A cost-share system where the partial cost of a pallet is passed-through from the purchaser to the receiver of the pallet

Cost-Per-Trip

Average cost of pallet use for a single one-way trip

D

Deck

One or more boards or panels comprising the top or bottom surface of the pallet

Deck Mat

Assembly of deckboards and stringerboards, forming the deck of a block pallet

Deckboard

Element or component of a pallet deck, oriented perpendicular to the stringer or stringerboard

Deckboard Spacing

Distance between adjacent deckboards

Deckboard Span

Distance between deckboard supports (stringers, stringerboards or blocks)

Deflection

The amount of deformation or bending in a pallet or pallet component under load

Dimensions – See Pallet Dimensions

Double-Face Pallet

A pallet with top and bottom decks

Double-Wing Pallet

A pallet with top and bottom deckboards extending beyond the edges of the stringers or stringerboards

Drive Screw Nail

Helically (continuous spiral) threaded pallet nail

E

Economic Life

Output from PDS© program which identifies the number of trips the pallet will make, provided it is properly repaired, which maximizes a return on investment

Exchange Pallet

A pallet intended for use among a designated group of shippers and receivers where ownership of the pallet is transferred with the ownership of the unit load; common pool pallet

Expendable Pallet

A pallet intended for a series of handlings during a single trip from shipper to receiver; it is then disposed; see Shipping Pallet

F

Fastener

A mechanical device for joining pallet components such as nails, staples, bolts or screws

Fastener Shear Index

Relative measure of shear resistance of the pallet fastener

Flush Pallet

A pallet with deckboards flush with the stringers, stringer-boards or blocks along the sides of the pallet

Fork Entry

Opening between decks, beneath the top deck or beneath the stringer notch to admit forks

Four-Way Block Pallet

A pallet with openings at both pallet ends and along pallet sides sufficient to admit hand-pallet jacks; full four-way entry pallet

Free Span

The distance between supports in a warehouse rack

H

Hand (Wheel) Jack Opening

Space provided in the bottom deck to allow pallet jack wheels to bear on the floor

Handling

A single pick-up, movement and set-down of a loaded or empty pallet

Hardened-Steel Nail

Heat-treated and tempered steel pallet nail with a MIBANT angle between 8 and 28 degrees

Hardwood

Wood from broad-leaved species of trees (not necessarily hard or dense)

Helical Nail

Helically (continuous spiral) threaded pallet nail, see also Drive Screw Nail

I

Inner Deckboard

Any deckboard located between the end deckboards

J

Joint

Intersection and connection of components, often identified by location within the pallet as the end joint, center joint and corner joint

L

Length

Refers to the stringer or stringerboard (in block pallets) length; also refers to the first dimension given to describe a pallet i.e., 48″ x 40″, where 48″ is the pallet stringer/stringerboard length

Life to First Repair

Output from PDS© program which is equivalent to the number of trips the pallet will last before needing repair

Line Load

The weight of a unit load concentrated along a narrow area across the full length or width of the pallet

Load Bearing Surface

Actual area of material in contact with and supporting a unit load

M

MIBANT Angle

The bend angle in a fastener shank when subjected to a MIBANT test

MIBANT Test

(Morgan Impact Bend Angle Nail Tester) – Standard impact nail tester used in the pallet and lumber industry as an indication of impact bend resistance of nails or staples

N

Nail

Fastener made from endless wire by cutting a point and forming a head at the shank end opposite the point

NATIONAL WOODEN PALLET AND CONTAINER ASSOCIATION

A national association with the goal of promoting the design, manufacture, distribution, recycling, and sale of pallets, containers, and reels

Non-Reversible Pallet

A pallet with bottom deckboard configuration different from top deck

Notch

Cutout in lower portion of the stringer to allow entry for the fork tine, usually 9″ in length, 1 1/2″ in depth

Notched Stringer

A stringer with two notches spaced for fork-tine entry, (partial four-way entry)

O

Opening Height

The vertical distance measured between decks, from the floor to the underside of the top deck, or from the floor to the top of the stringer notch

Overall Height

The vertical distance measured from the floor to the top side of the top deck

Overhang

The distance the deck extends from the outer edge of the stringer or stringerboard; wing; lip; distance the unit load extends beyond the deck

P

Pallet

A portable, horizontal, rigid platform used as a base for assembling, storing, stacking, handling and transporting goods as a unit load, often equipped with a superstructure

PALLET DESIGN SYSTEM© (PDS©)

Reliability-based computer-aided design (CAD) program, for determining the safe load carrying capacity, performance, life and economy of wooden pallets

Pallet Dimensions

When specifying pallet size, the stringer or stringerboard (block pallet) length is always expressed first; for example, a 48″ x 40″ pallet has a 48″ stringer or stringerboard and 40″ deckboards

Pallet Jack

Hand-propelled wheeled platform, equipped with a lifting device for moving palletized unit loads

Pallet Life

The period during which the pallet remains useful, expressed in units of time or in the number of

one-way trips

Panel Deck Pallet

Pallet constructed with composite or structural panel top deck

Partial Four-Way Stringer Pallet

A pallet with notched stringers

Post Pallet

A pallet fitted with posts or blocks between the decks or beneath the top deck; see block pallet

Q

Quality

Consistent performance of a uniform product meeting the customer’s needs for economy and function

R

Racked Across Deckboards

Output from PDS© program describing the maximum load carrying capacity and deflection of a pallet where the rack frame supports the pallet only at the ends of the deckboards

Racked Across Stringers

Output from the PDS© program describing the maximum load carrying capacity and deflection of a pallet where the rack frame supports the pallet only at the ends of the stringers or stringer boards

Repair

To remake in order to use again

Recycling

A pallet, container or reel that has been used, discarded, salvaged, repaired and which passes through a cycle again

Rental Pallet

A pallet owned by a third party, different from the actual pallet user

Returnable/Reusable Pallet

A pallet designed to be used for more than one trip

Reversible Pallet

A pallet with identical top and bottom decks

S

Shipping Pallet

Pallet designed to be used for a single one-way trip from shipper to receiver; it is then disposed; see Expendable Pallet

Shook

Cut-to-size pallet parts to be assembled into pallets

Shook Grade

The classification of the quality of pallet parts relative to performance characteristics based on size and distribution of defects, independent of wood species

Single-Wing Pallet

A pallet with the top deckboards extending beyond the edges of the stringers or stringer-boards with the bottom deckboards flush (if present)

Skid

A pallet having no bottom deck

Slave Pallet

Pallet, platform or single, thick panel used as a support base for a palletized load in rack-storage facilities or production systems

Soft Nail

Pallet nail with a MIBANT angle equal to or greater than 47 degrees

Softwood

Wood from coniferous or needle-bearing trees (not necessarily soft or low density)

Solid Deck Pallet

A pallet constructed with no spacing between deckboards

Span

The distance between stringer or block supports

Stevedore Pallet

A pallet designed for use on seaport shipping docks, normally of heavy-duty, double-wing construction

Stiff-Stock Steel Nail

Pallet nail made of medium-high carbon steel without heat treatment and tempering with MIBANT angle between 29 and 46 degrees

Strap Slot

Recess or cutout on the upper edge of the stringer or the bottom of the top deckboard to allow tie-down of a unit load to the pallet deck with strapping/banding, also called the banding notch

Strapping

Thin flat bands used to secure load to pallet

Stringer

Continuous, longitudinal, solid or notched beam-component of the pallet used to support deck components, often identified by location as the outside or center stringer

Stringerboard

In block pallets, continuous, solid board member extending for the full length of the pallet perpendicular to deckboard members and placed between deckboards and blocks

T

Take-It-Or-Leave-It Pallet

A pallet fitted with fixed cleats on the top deckboards to permit fork truck tines to pass beneath the unit load and remove it from the pallet

Top Cap

Panel to be placed on top of a unit load to allow for tight strapping without damaging the unit load

Top-Deck of the Pallet

The assembly of deckboards comprising the upper load-carrying surface of the pallet

Trip

Consists of four to six handlings of a pallet

Two-Way Entry Pallet

A pallet with un-notched solid stringers allowing entry only from the ends

U

Unit Load

Assembly of goods on a pallet for handling, moving, storing and stacking as a single entity

W

Warehouse Pallet

A double-face multiple trip returnable pallet intended for general warehouse use

Wing

Overhang of deckboard end from outside edge of stringer or stringer-board